First, the underlying logic of welding parameter optimization

1.1 Synergies between parameters

Welding current, voltage, welding speed, gas flow and other parameters are not independent, but interrelated. For example, the current determines the penetration depth, the voltage affects the penetration width, and the welding speed balances the heat input with the cooling rate. A multi-parameter linkage model should be established to avoid the linkage problem caused by single parameter adjustment.

Case study: A pressure vessel manufacturer found that the porosity of the weld was high, and through DOE (Experimental design) analysis, it was found that insufficient gas flow combined with excessive welding speed led to the failure of protective gas cover, and the porosity decreased by 90% after adjustment.

1.2 Necessity of dynamic optimization

The traditional static parameter setting is difficult to deal with variables such as material thickness change and ambient temperature fluctuation. Modern welding equipment (such as digital welding machine) supports real-time feedback adjustment, and collects arc stability, molten pool temperature and other data through sensors to dynamically modify parameters.

Second, core parameter optimization skills

2.1 Golden ratio of current and voltage

Formula method: U=14+0.05I (suitable for carbon steel MIG welding), but it needs to be modified according to the base material

Rule of thumb: For every 100A current increase, the penetration depth increases by 1.5-2mm, and the voltage needs to be increased by 1-2V simultaneously

Error warning: Simply increasing the current will lead to an increase in spatter, which needs to be adjusted with voltage

2.2 Accurate control of welding speed

Critical speed: Exceeding a certain threshold will lead to hump pass, calculation formula: V_c = k · (I/(T · √(U))), k is the material factor

Efficiency balance: under the premise of ensuring penetration, increasing speed by 20% can reduce energy consumption by 15%

2.3 Optimization strategy of protective gas

Mixed gas ratio: 80% Ar+20% CO₂ for carbon steel, 98% Ar+2% O₂ for stainless steel

Gas flow calculation: Q=0.04D² (D is the nozzle diameter mm), wind speed more than 1.5m/s need to increase 30% flow

2.4 Influence of extension length of welding wire

Formula: L= (0.005-0.01) · I (mm), too long will cause the welding wire to fuse, too short affect the visibility

Third, intelligent optimization technology application

3.1 Artificial Intelligence algorithm

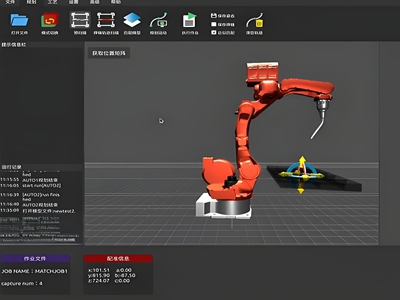

Neural network model: input current, voltage, speed and other parameters, and output weld forming prediction (Figure 1)

Reinforcement learning: By automatically exploring the optimal parameter combination through the incentive mechanism, the yield of an automobile factory increased by 7% after application

3.2 Digital Twin Technology

Virtual welding system: Simulate different parameter combinations in digital twins to predict defects in advance (Figure 2)

Real-time mapping: Synchronize physical welding process data to a virtual model and dynamically adjust parameters

3.3 Visual detection closed loop

High-speed camera: collect the molten pool image and identify the melting width and depth through image processing (FIG. 3)

Closed-loop control: the detection data is fed back to the welder in real time to realize parameter adaptive adjustment

Fourth, industry application scenarios

4.1 Aluminum alloy welding

Parameter characteristics: high-frequency pulse current (50-200Hz) is required, and voltage fluctuation is controlled at ±0.5V

Case: A rail car factory adopts variable polarity TIG welding, and the weld strength is increased by 12% after parameter optimization

4.2 Stainless Steel Welding

Heat input control: line energy ≤15kJ/cm to avoid intergranular corrosion

Optimization: Using pulsed MAG welding, the combination of parameters (I=200A, U=25V, V=30cm/min) can reduce the heat affected zone

4.3 Dissimilar metal welding

Parameter matching principle: Based on materials with lower melting point, the current is reduced by 10-15%

Successful case: Titanium steel dissimilar welding using cold metal transition (CMT) technology, parameters optimized interface bonding strength up to 85% base metal

Fifth, common problem diagnosis and optimization

5.1 Splash control

Spatter rate formula: S=0.003I² -0.2IU +5 (%)

Optimization measures: Reduce the short-circuit current rise rate, adjust the inductance value (0.1-0.3mH)

5.2 Weld forming defects

Non-fusion: Increase current by 5-10%, or reduce welding speed by 5-8%

Edge bite: Reduce the voltage by 1-2V, or increase the Angle of the torch by 5-10°

5.3 Stomatal prevention

Gas protection effectiveness formula: Q/V≥0.8 (Q flow L/min, V welding speed m/min)

Process improvement: The drag gun Angle is 10-15° to avoid gas turbulence

Sixth, future development trend

1.AI autonomous optimization system: Integrated machine learning algorithm to achieve automatic parameter optimization

2. Laser-arc composite welding: Through multi-energy collaborative control, expand the parameter optimization space

3. Blockchain parameter traceability: Establish a blockchain database of welding parameters to achieve quality lifecycle management

Conclusion

Welding parameter optimization is a systematic engineering integrating experience knowledge and advanced technology. By mastering the inherent laws between parameters, combined with intelligent algorithms and digital tools, enterprises can significantly improve welding quality and production efficiency. In the future, with the in-depth development of Industry 4.0, parameter optimization will shift from passive adjustment to active prediction, providing continuous impetus for the high-quality development of the manufacturing industry.

Appendix: Welding parameter optimization quick reference table (part of the parameter range reference)

|

Parameter Type |

Low Carbon Steel MIG Welding |

Stainless Steel TIG Welding |

Aluminum Alloy MIG Welding |

|

Current (A) |

120-350 |

80-200 |

150-400 |

|

Voltage (V) |

18-32 |

10-18 |

20-35 |

|

Welding Speed (cm/min) |

20-60 |

10-30 |

30-80 |

|

Gas Flow Rate (L/min) |

15-25 |

8-12 |

20-30 |

(Note: The specific parameters need to be adjusted according to factors such as base metal thickness and groove form)